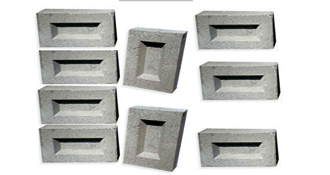

Fly ash brick (FAB) is a building material,

specifically masonry units, containing

class C or class F fly ash and water.

Compressed at 28 MPa (272 atm) and

cured for 24 hours in a 66 °C steam bath, then toughened with an air entrainment

agent, the bricks last for more than

100 freeze-thaw cycles. Owing to the

high concentration of calcium oxide in

class C fly ash, the brick is described as

"self-cementing". The manufacturing

method saves energy, reduces mercury

pollution, and costs 20% less than

traditional clay brick manufacturing.

The raw materials

Gypsum acts

as a long term strength gainer. The

chemical reaction due to the aluminum

paste provides AAC its distinct porous

structure, lightness, and insulation

properties, completely different

compared to other lightweight concrete

materials. The finished product is a

lighter Block - less than 40% the weight

of conventional Bricks, while providing

the similar strengths.

1) Loss on Ignition (LOI); fly ash loses

weight when it burns at about 1000 °C

due to presence of carbon and water.

The weight loss happens due to carbon

combustion and moisture evaporation is

called "Loss on Ignition(LOI)". This is

expressed as percentage. The lower the

loss of Ignition, the better will be fly ash.

As per BIS it should not be more than 5%.

2) Fineness; the fine fly ash has more

surface area available to react with lime,

thus more will be the pozzolanic activity

of fly ash. The greater pozzolanic activity

contributes to the strength of fly ash brick. As per BIS it should not be more

than 320 m2/kg.

3) Calcium (CaO) content; the pozzolanic

reactivity of fly ash is more in high

calcium fly ash. The greater the

pozzolanic activity leads to higher the

strength of fly ash brick. As per ASTM

C618 fly ash is classified into two; Class

C contains more than 10% lime and

Class F fly ash contains less than 10%

lime.

Advantages

It reduces dead load on structures due

to light weight (2.6 kg, dimension: 230 mm X 110 mm X 70 mm).

Same number of bricks will cover more area than clay bricks

High fire Insulation

Due to high strength, practically no breakage during transport and use.

Due to uniform size of bricks mortar required for joints and plaster reduces almost by 50%.

Due to lower water penetration seepage of water through bricks is considerably reduced.

Gypsum plaster can be directly applied on these bricks without a backing coat of lime plaster.

These bricks do not require soaking in water for 24 hours. Sprinkling of water before use is enough.

Disadvantages

Mechanical strength is low, but this can be rectified by adding marble waste or mortar between blocks.

2. Limitation of size. Only modular size

can be produced. Large size will have

more breakages.

3. It is only good for the places like

subtropical area or area where climate is

warm because it doesn't absorbs heat.

But during cold it is not helpful.